INSTALLATION ON EXTERNAL THERMAL INSULATION

Recent legislation on energy savings stipulate efficiency requirements for buildings. As a result, the use of thermal insulation is becoming increasingly widespread in homes, and therefore the need to implement an expert installation on such surfaces.

Geopietra® can boast extensive knowledge on the subject, and after many years of development and rigorous laboratory testing can offer a guaranteed integrated system for installing Murogeopietra on external thermal insulation.

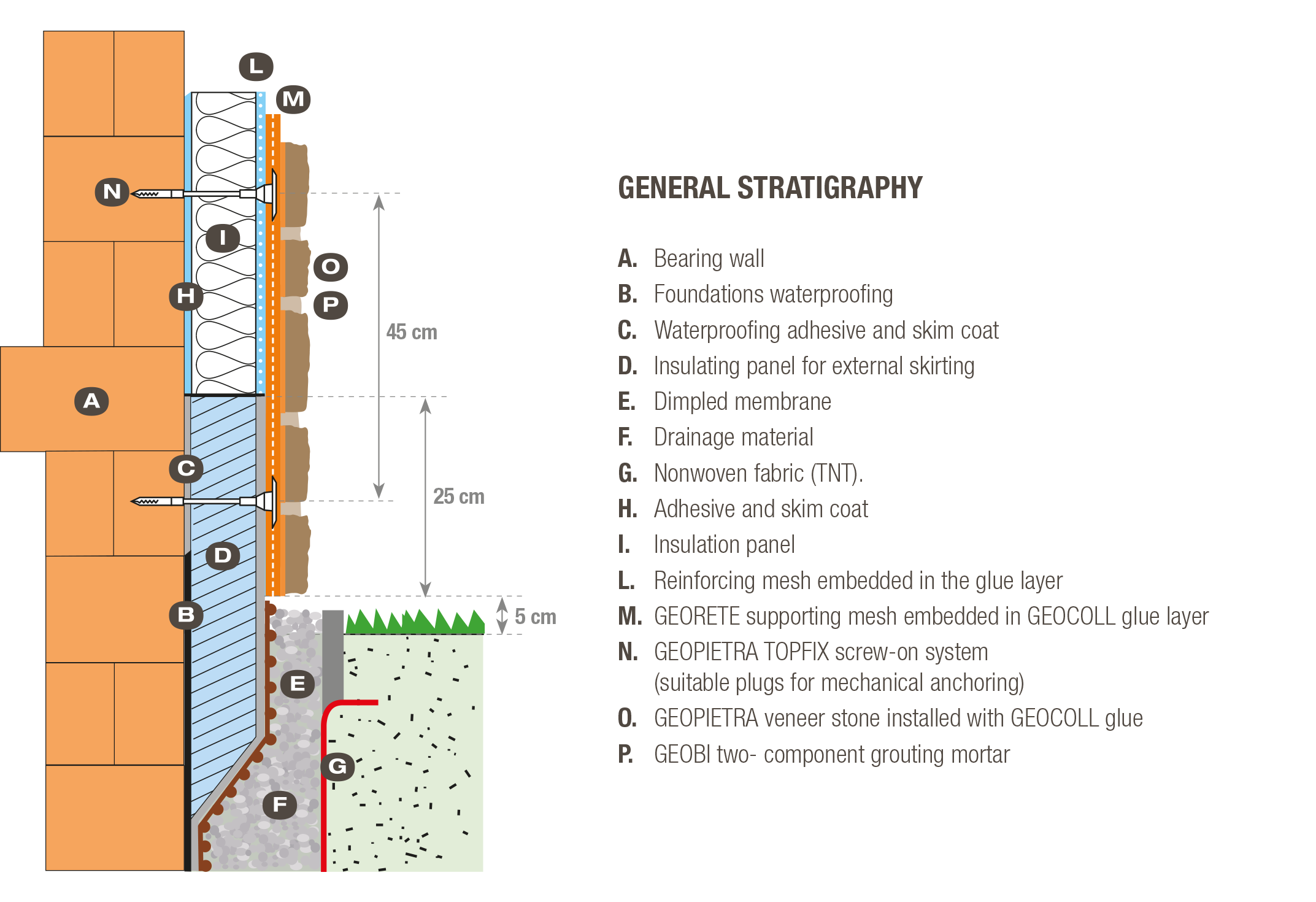

MUROGEOPIETRA on external thermal insulation requires special care during design and implementation, both in terms of technical and aesthetic factors. When sizing window frames and sills, rails and door frames, it is important to remember that a surface covered with Geopietra manufactured stone veneer will protrude approximately 6-7 cm from the insulation, whereas the TERRAKOTTA covering will protrude approximately 2-3 cm (thickness varies depending on the model). Chapter 11.1 illustrates useful strategies for installation on external thermal insulation around windows.

Specific strategies for the guaranteed procedure:

The materials and procedures used in external thermal insulation systems must comply with ETAG 004 certification.

Manufacturers of external thermal insulation must guarantee a capacity of 70 kg/m2.

The area of adhesion on the insulation panel on the structure must exceed 60% of the area of the panel itself.

On the layer of reinforced plaster created on the insulation panel there must have been no treatment using primers or finishes before installing the Murogeopietra.

The procedure must be carried out by qualified personnel in accordance with standard work practices and technical standards.

The insulation system must be fixed mechanically using special studs for thermal insulation systems, featuring the GEOPIETRA TOP FIX screw-on system. The studs should be of a suitable length, according to the insulation thickness, and should have at least 25mm expansion clearance inside the masonry, depending on the backing.

The anchoring studs must pass through the consolidated layer of reinforcement plaster and the GEORETE fibreglass mesh substrate embedded in the still fresh layer of GEOCOLL® adhesive.

The insulation system should be fixed mechanically possibly by the fitter of the GEOPIETRA stone veneer.

Anchoring holes for fixing the insulation system mechanical fixing are drilled in the properly set reinforced smoothing layer of the ETAG 004-certified thermal insulation.

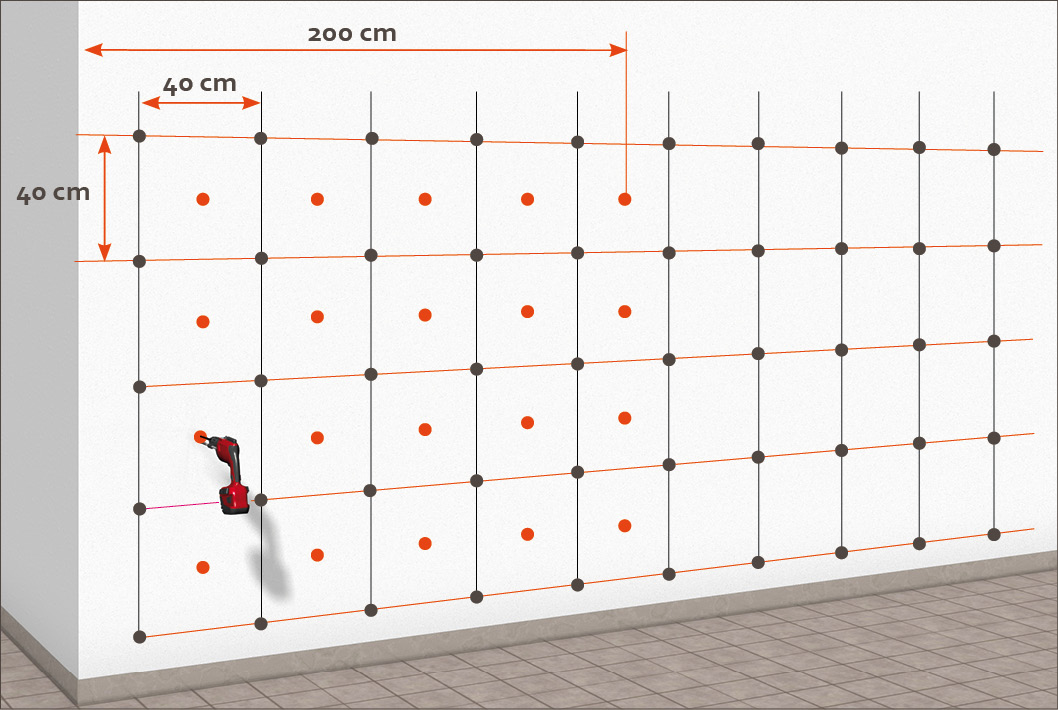

The studs are positioned according to a 40x40cm raster layout, corresponding to 6.37 studs per square metre. In the perimeter areas (200cm from the building corner), there must be 12.49 studs per square metre. This data is indicative and must be verified according to the 1991-1 standard.

DRILLING SCHEME

TOPFIX

TOP FIX Screw wall plug with cap

Thermal conductivity: λ 10 dry < 0,002 W/mK

SHANK: Ø 8 mm~ / PLATE: Ø 60 mm

CATEGORIES: A Concrete / B Solid brick / C Brick

D Light vibrated concrete / E Foam concrete

1. DRILLING AND MILLING Use an 8mm bit drill to make holes of at least 10mm depth in addition to the anchoring depth. Clean the holes thoroughly. Countersink the hole to obtain a 16-18mm diameter flare to allow for flush screwing of the stud plate.

2. FIRST MASONRY SMOOTHING USING GEOCOLL Use a smooth knife to apply a 2mm layer of soft GEOCOLL adhesive to the backing.

3. MARKING THE HOLES Although the milled holes are covered with adhesive, they remain visible because they form a small bubble that can be highlighted by perforating it with a tip prior to the application of the GEORETE mesh substrate.

4. LAYING THE GEORETE MESH SUBSTRATE Bury the GEORETE large fibreglass mesh by overlapping the joints by at least 10 cm.

5. INSERTING GEOPIETRA TOP FIX STUDS Immediately insert the Geopietra Top Mix studs by hand into the pre-drilled holes.

6. SCREWING IN AND SEALING THE STUDS Use a screwdriver to screw in flush with the surface top. Any studs that do not adhere should be removed or replaced. Insert the closing plugs provided with the Geopietra Top Fix studs.

7. SURFACE FINISH Apply an even layer of Geocoll adhesive to cover the mesh and stud heads completely. Especially when the cladding is installed “dry”, i.e. the joints are not filled with mortar, make sure the stud heads are fully buried in the smoothing adhesive and add extra GEOCOLL, if necessary. When the adhesive has properly set, the wall is ready for the installation of the stone veneer.

8. THE MUROGEOPIETRA INSTALLATION Install murogeopietrs only after completion of the installation of the laying insulation system to prevent dirtying the cladding. GEOPIETRA stone veneer must be laid not before 5-7 days from the date of installation of the insulation panels. The structural expansion joints that are already sealed should be left free.

Care should be taken to properly install murogeopietra, in accordance with the manufacturer’s technical guidelines set out in this installation manual. (Attached to each supply and downloadable from the website www.geopietra.com).

In the case of existing insulation the only possible assessment to carry out regards the integrity of the surface layer, whereby adhesion to the base will be unknown. As a result the following procedure only concerns dealing with the visible part and increasing mechanical anchoring.

Clean the visible layer of plaster thoroughly, removing worn or unstable parts and restoring with special insulation adhesive or Geocoll® adhesive if necessary.

Insert the Georete support mesh in a double application of Geocoll®. Secure the assembly with plugs suited to thermal insulation forming a strong secure 35x35 cm grid. When choosing wall plugs it is important to know the base material used in order to choose the most suitable plugs and have the maximum grip. The murogeopietra can be installed once completely dry.

If the thermal insulation is clearly fragile with surface cracks and considerable water infiltrations the only solution is total replacement, in which case we would recommend the cladding guaranteed procedure. (see GUARANTEED PROCEDURE)