16 | TERRAKOTTA: BRICK SLIPS

Using the same technology as manufactured stone veneer, Geopietra®, has produced a select range of brick slips. This solution is complete with models in natural version chosen in the best brick factories in Northern Europe. Individual models from popular areas are still produced with manual procedures, cut to a thickness of 25 mm from solid pieces.

The Terrakotta brick slips in the natural version has retained the charm and characteristics of traditional brick tried and tested throughout the centuries. Mixes passed down through generations and perfected in terms of cohesion and grip are baked in ovens at a temperature between 800°C-1200°C.

The Terrakotta brick slips in the manufactured version realistically produce the colours and textures of natural terracotta, adding rustic charm to recovered bricks.

Also designed and optimised for use with all models of Geopietra® manufactured stone, manufactured brick has exceptional technical qualities and freeze resistance characteristics. As a result of its characteristics, Geopietra® manufactured brick enhances the efficiency of thermal insulation and makes an external thermal insulation structure more robust and resistant by adding significant benefits.

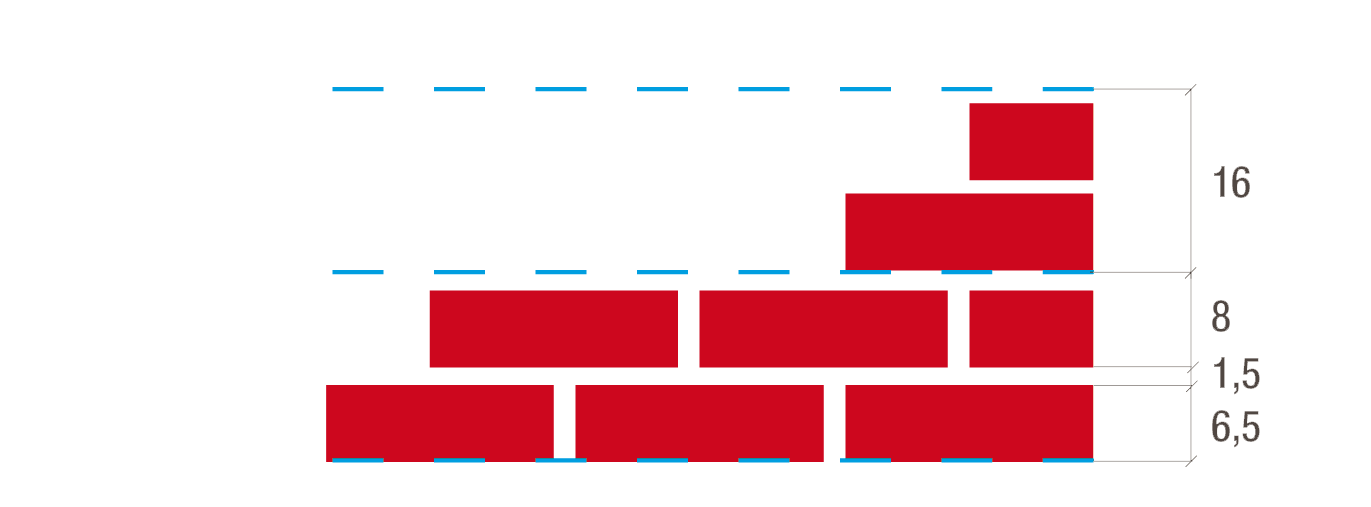

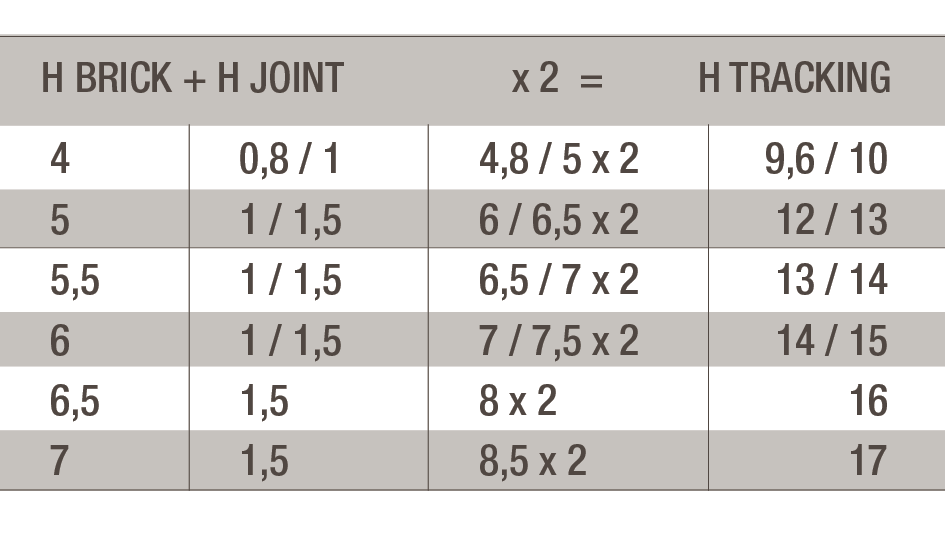

Calculate joint thickness to obtain whole multiples to be distributed over the height of the wall. Mark out horizontal lines equivalent to the sum of the brick height and the corresponding joint (or its multiples). Keep courses in line with a straight edge and level.

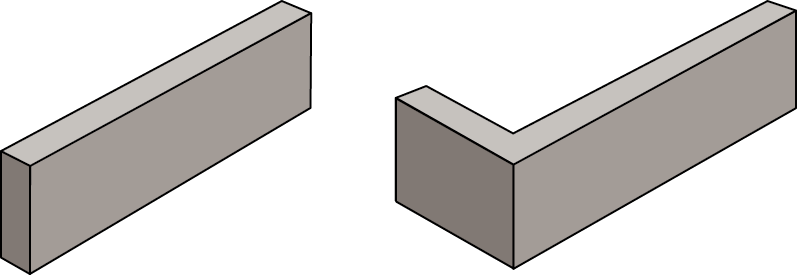

Model-specific information is outlined below to speed up the operation: The brick covering can be installed from the bottom upwards or vice versa, as thanks to Geocoll® there are no issues with slippage. Corners should be installed first at the beginning of each course, alternating long and short sides.

NATURAL BRICK SLIPS

After suitable drying, saltpetre formation is normal. For removal, simply apply a solution with water and hydrochloric acid (80% water + 20% hydrochloric acid) or an equivalent product that can be painted with a surface brush. Protect hands, face or other parts of the body with gloves from possible splashes. Do not use a water-repellent product or similar. Geopietra disclaims any responsibility for any damage resulting from the use of any product. A properly performed masonry does not require any treatment after cleaning.

1. Clean any processing residue off the surface of corner strips before applying the adhesive.

2. The Geocoll® adhesive must always be placed on the back of the corner and stuck onto the brick and wall firmly with a trowel, working with a wet-on-wet technique.

3. Stick the corner down using slight pressure and small vertical movements (up/down) until a suction effect is obtained. Alternate long and short sides so the installation of subsequent courses is staggered.

4. If necessary cut the slips with a diamond blade or break it with a hammer.

5. The Geocoll® adhesive must always be placed on the back of the brick and the wall, working with a wet-on-wet technique.

6. Install the slips using slight pressure and small sideways movements (right/left) until excess adhesive is pressed out and the piece grips by itself. Remove excess Geocoll® before installing the next brick. Always stagger vertical joints.

7. Use GeoBi/F fine grain mortar with the piping bag provided to fill joints. DO NOT APPLY MORE MORTAR THAN IS REQUIRED ON A GRADUAL BASIS. Do not use WET spatulas, brushes or sponges.

8/9. CARRY OUT MANUAL CONSISTENCY TESTS to verify workability times. When surface water is no longer present (dry fingers) the material can be worked. It is only in finishes with a trowel or spatula that the mortar must be worked when still wet.

10. Remove excess material and press the remainder into the joints with a wooden stick, working it according to need and preference. The aesthetics of Geopietra® brick slips are emphasised by the finish, and as with the manufactured stone there are various different styles. (see section 15)